A denitrification filter and its operating method

A denitrification filter and filter technology, which is applied in chemical instruments and methods, anaerobic digestion treatment, water pollutants, etc. The effect of water quality compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

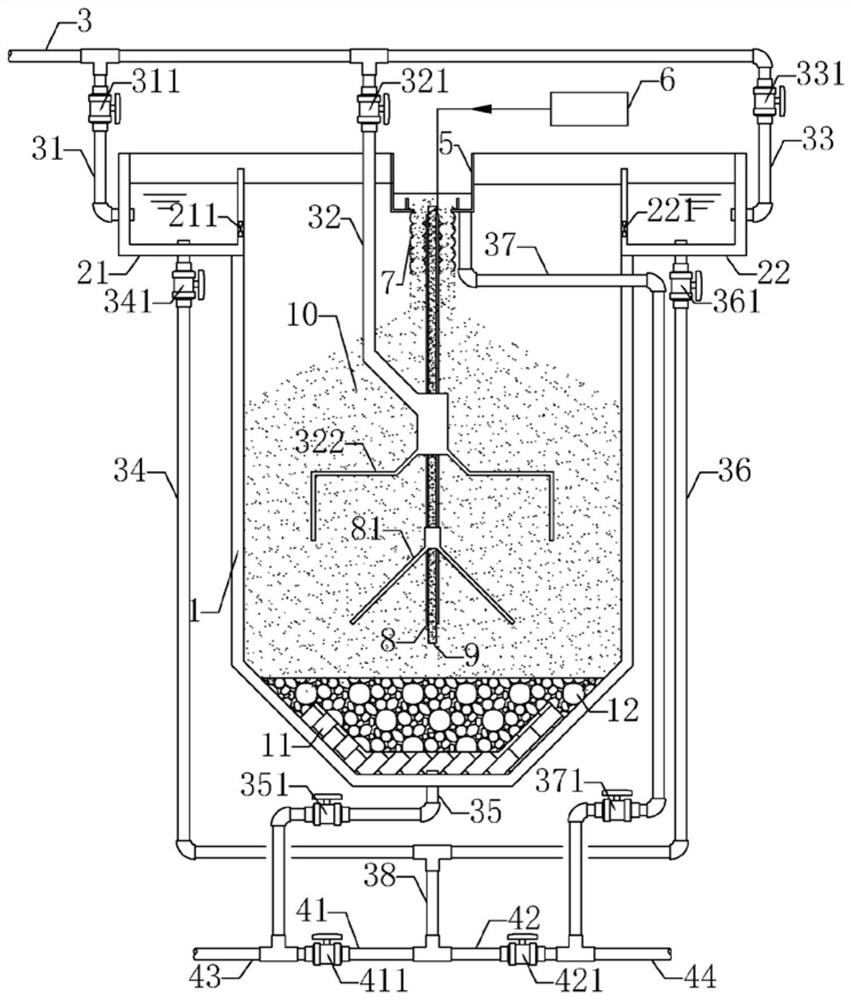

[0051] The denitrification filter of the present embodiment, such as figure 1 As shown, it includes a cuboid filter body 1, a water inlet pipe 3 and a square sump A21 and a square sump B22 fixedly arranged on the outer side wall of the upper part of the filter body 1. Sand vessel 5; wherein: the water inlet pipe 3 passes into the sump A21, the filter body 1 and the sump B22 through the parallel water diversion pipe A31, water diversion pipe B32 and water diversion pipe C33; the bottoms of the sump A21 and the sump B22 are respectively The external connection pipe A34 and the connection pipe B36; the connection pipe A34, the connection pipe B36 and the confluence pipe 38 are connected by a tee at the bottom of the filter body 1; the confluence pipe 38 is connected to the connection pipe D41 and The connecting pipe E42 is connected; the bottom end of the filter body 1 is externally connected with an outlet pipe 35, and the outlet pipe 35 and the connecting pipe D41 are also comm...

Embodiment 2

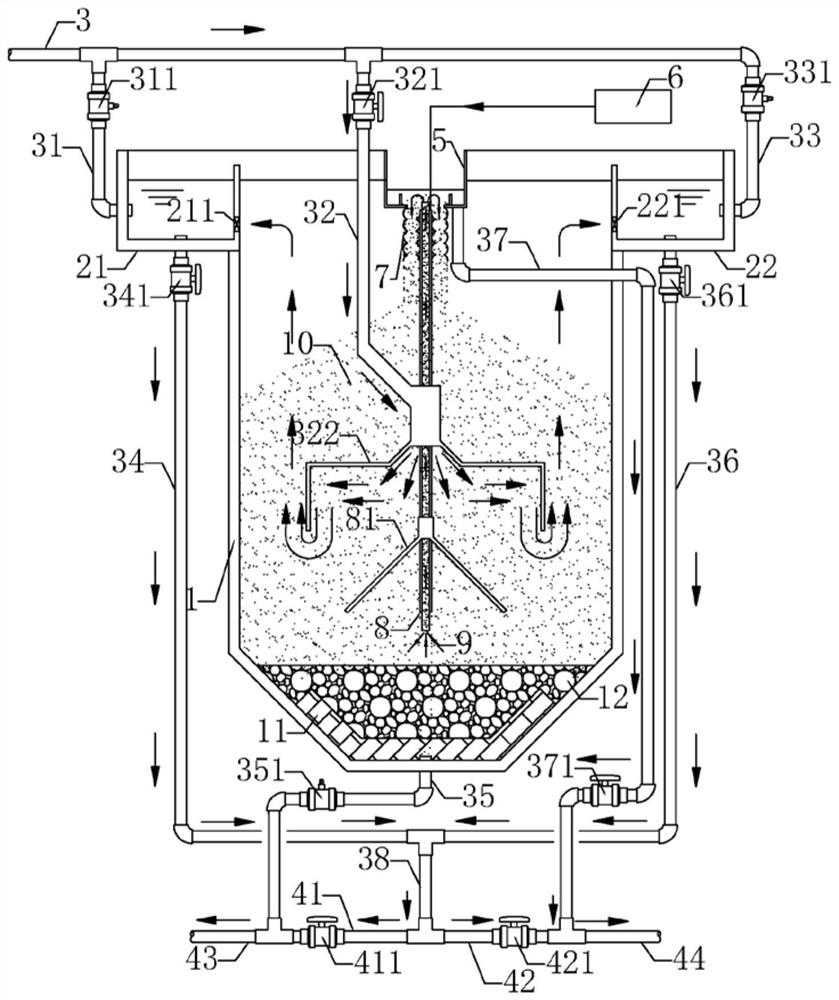

[0054] The denitrification filter of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are: the bottom end of the sand washer 5 is also connected with a sand suction pipe 9 inserted into the bottom of the filter material 10, and the outer wall of the sand suction pipe 9 is covered There is an air pipe 8; the bottom end of the sand washer 5 is also connected to a filter material pipe 7 leading to the filter body 1, so as to ensure repeated cleaning of the filter material and maintain the processing performance of the filter material. The water distribution pipe B32 is inserted into the inside of the filter material 10, and its bottom is gap-type socketed on the outer wall of the air pipe 8, and a water outlet is left at the bottom to ensure that the water is discharged downward so as to facilitate full contact between the sewage and the filter material; the lower part of the water outlet The outer wall of the air pipe 8 is als...

Embodiment 3

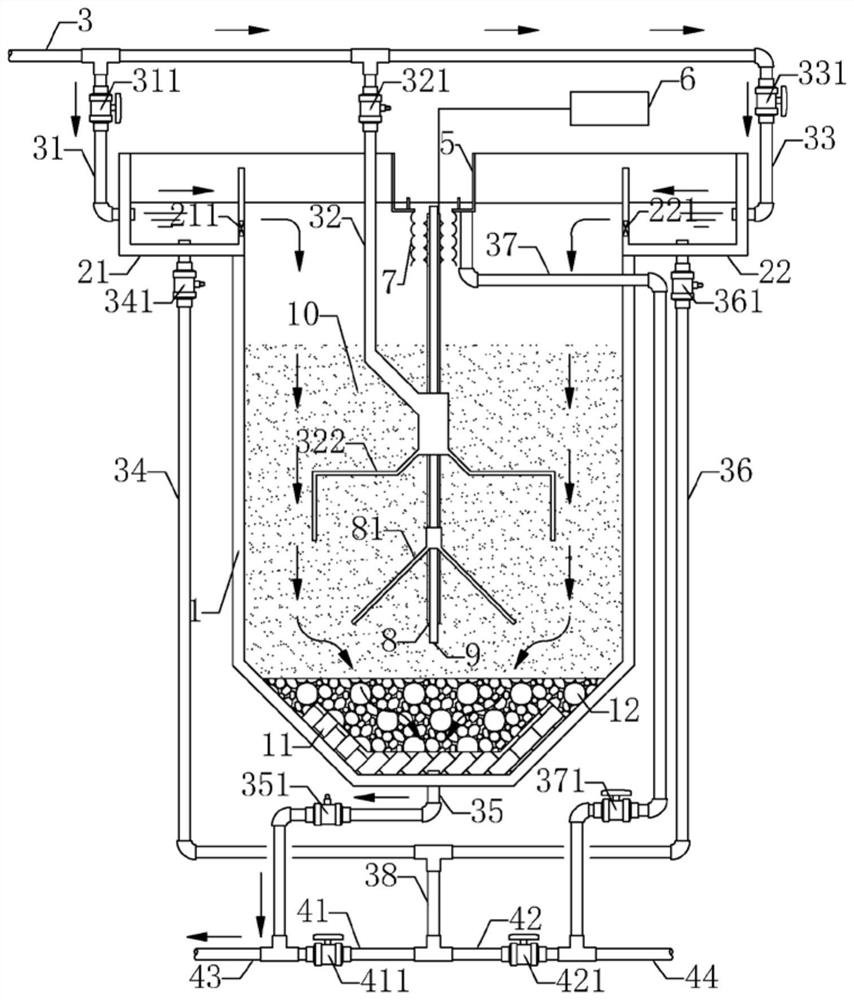

[0062] The denitrification filter of the present embodiment, the basic structure is the same as embodiment 2, and its low-load operation method, the steps are: as image 3 as shown,

[0063] Step 1. Valve setting: open valve A311, valve C331 and valve E351; close valve B321, valve D341, valve F361, valve G371, valve H411 and valve I421;

[0064] Step 2, water flow: the sewage enters the water distribution pipe A31 and the water distribution pipe C33 from the water inlet pipe 3, and then enters the sump A21 and the sump B22 respectively, and then enters the filter body 1 through the water hole A211 and the water hole B221 respectively;

[0065] Step 3, reaction: the sewage fully contacts and reacts with the filter material 10 from top to bottom, and the treated water passes through the supporting layer 12;

[0066] Step 4, flow diversion: after the water passing through the supporting layer 12 is collected by the water distribution device 11, after being discharged from the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap